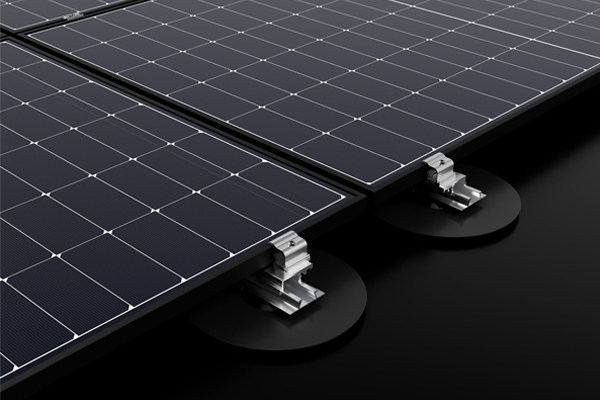

As solar installations expand globally, more attention is being paid not only to efficiency and structural strength, but also to the environmental footprint and durability of mounting systems. In ground-mount solar arrays, the choice of base materials and mounting design can significantly impact both performance and sustainability. One of the promising innovations is the integration of EPDM (ethylene propylene diene monomer) rubber layers or pads within ground mount structures. EPDM is a durable synthetic rubber known for excellent weather resistance, UV stability, wide temperature tolerance, and long service life. In SSP India’s ground mount designs, EPDM is used as a cushioning and sealing medium—absorbing shock, dampening vibrations, and protecting solar modules and structural components from mechanical fatigue over time. Because EPDM is flexible and resilient, it adapts to micro-movements caused by temperature fluctuations and wind, reducing stress at joints and fasteners. It also helps in water drainage management under panels, minimizing water pooling and related corrosion or substrate damage. SSP India’s use of EPDM rubber in solar ground mounts reflects a move toward more eco-balanced structural systems that minimize material degradation and reduce maintenance cycles.

Beyond just material advantages, these EPDM-integrated mounts enhance the sustainability and longevity of solar installations. By reducing structural fatigue and sealing interfaces effectively, components last longer, repair needs drop, and lifecycle emissions from replacements are cut. EPDM itself is a stable polymer with low environmental leaching risk and good recyclability at end of life, making it a more sustainable choice compared to some coatings or adhesives that degrade or emit harmful substances over time. Moreover, EPDM helps in thermal decoupling—slowing heat transfer from the ground into the module framework—and can act as an insulative layer, improving temperature stability. From a design standpoint, SSP India can tailor EPDM thickness, durometer (hardness), and layout to match soil conditions, load design, and panel footprint, thereby optimizing both strength and eco-credentials in the mount structure. The result is a ground mounting system that not only supports high performance solar arrays but also aligns with green goals and longer service horizons

FAQs on EPDM & Eco-Friendly Ground Mounts

What role does EPDM play in water management under panels?

EPDM layers help channel water, prevent pooling beneath modules, and protect underlying structures or foundations from moisture damage or corrosion.

Can EPDM be customized for different solar mount designs?

Absolutely. SSP India can vary EPDM thickness, durometer, patterning or segmentation to match soil types, wind loads, module size, and differential expansion.

Why choose SSP India for EPDM-integrated sustainable mounts?

SSP India already uses EPDM rubber in its ground mount designs to provide cushioning, durability, and sustainable performance. Their engineering capability ensures the EPDM is optimized for your site, load profile, and environmental conditions.

Why use EPDM rubber in solar ground mounting systems?

Because EPDM offers excellent weathering, UV stability, flexibility, and long service life. It cushions mechanical stresses and enhances durability in solar mounts.

How does EPDM improve structural reliability?

It absorbs vibration, accommodates thermal expansion stresses, and prevents micro-movements at joints, which reduces fatigue on rails, bolts, and mounting frames.

Is EPDM environmentally friendly?

Yes — EPDM is chemically stable, resists degradation, has low leaching, and at end of life can be recycled or disposed with minimal hazard compared to some adhesives or coatings.